Kaombo

Operator: Total

Location: West Africa Block 32

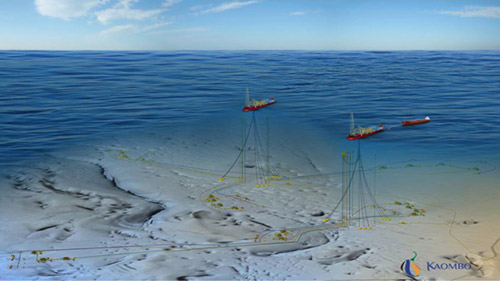

This Total’s Project is located in Block 32 at about 150 km from the Angolan coast and covers a total surface of 5090 km2. The Kaombo area itself covers the Gindungo, Gengibre, Caril, Canela, Louro, Mostarda and Salsa Provisional Development Areas (DA) with a cumulative surface of about 640 km2, in water depths ranging from 1400m to 2000m.

Main information regarding this Project:

– Stand alone development of 6 fields and 9 reservoirs: Gengibre Oligocene, Gengibre Miocene, Gindungo Main, Gindungo Deep, Caril Oligocene (hub North); and Canela Oligocene, Mostarda West panel, Louro Oligocene and Louro Miocene reservoirs (hub South),

– Base case reserves amount to around 660 Mb (w/o Fuel Gas), over a production period of 20 years with 59 wells (33 production wells and 26 injector wells);

– Production by subsea wells connected via six hybrid loops to 2 converted turret-moored FPSO’s, both following the same design (concept ‘’design 1 – build 2’’) and designed for a 115 kbopd yearly production plateau;

– Full reservoir pressure maintenance by water injection;

– Artificial lift provided by riser-base gas-lift;

– Export of excess gas to Angola LNG liquefaction plant;

– Stabilised crude export by tankers (tandem offloading);

– FID : early 2014;

– Contract Awards : 1st Quarter 2014;

– First Oil : 3rd Quarter 2017 for the FPSO North, 2nd Quarter 2018 for the FPSO South and for Caril Field;

– Start of drilling campaign 18 months after FID;

– First Oil FPSO GGC with 13 wells 42 months after FID;

– First Oil FPSO CLM with 14 wells 50 months after FID (= FPSO GGC + 8 months);

– First Oil Caril Field 1 month after first oil FPSO CLM;

– End of full drilling & completion campaign between 5 to 6 years after start of drilling on FPSO GGC.

Scope of Work:

1. TOTAL E&P Angola documentation to review (on going):

• Project Design Basis (FEED) / Field Development Plan

• KAOMBO Project Quality Plan

• CLOV Project HSSE Manual

• Environmental Impact Assessment for this project

• Project Audit Schedule – performed by TOTAL to EPC contractors

• Audit reports (Project audits)

• NCR Management (Procedure)

• Emergency Response Plan – KAOMBO offshore Site

2. FPSO North

• Topsides Fabrication (Onshore)

– Oil Fiscal Metering System

– Inspection and Test Plans

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing applied

– Manufacturing Record Books Review

• FPSO & Topsides Integration (Onshore)

– Swivel

– Pipework

• FPSO & Topsides Commissioning (Onshore)

– Separation Systems

– Black Start Test

• Offshore Installation

– Flexible Risers & Umbilicals Hook-Up

– Caril Risers Hook-Up & Pre-Commissioning

• Offshore Commissioning

– Commissioning Activities witnessing after Riser Hook-Up

– Commissioning & Start-Up Procedures

– Black Start

– Witness Start-up activities

– 1st Oil

– Oil Export Metering Dynamic Commissioning

– Offloading Systems Commissioning

– Witness Offloading Operation

– Caril 1st Oil

– Offshore Safety practices and Environmental regulation

3. FPSO South

• FPSO South Refurbishment

– Inspection and Test Plans (ITPs)

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing (NDTs) applied

• Topsides Fabrication (Onshore)

– Metering & Chemical Injection Systems

– Oil Production/Treatment Module Fabrication

– Inspection and Test Plans

– NCR management

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing applied

– Manufacturing Record Books Review

• FPSO & Topsides Integration (Onshore)

– Swivel

– Pipework

– Modules Integration in Angola

• FPSO & Topsides Commissioning (Onshore)

– Gas Compressors System

– Black Start Test

• Offshore Installation

– Flexible Risers & Umbilicals Hook-Up

• Offshore Commissioning

– Commissioning Activities witnessing after Riser Hook-Up

– Commissioning & Start-Up Procedures

– Black Start

– Witness Start-up activities

– 1st Oil

– Oil Export Metering Dynamic Commissioning

– Offloading Systems Commissioning

– Witness Offloading Operation

– Offshore Safety practices and Environmental regulation

• X-Trees & Manifolds

– Quality Plan (Project Audits & NCR management)

– Inspection and Test Plans

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing

– Factory Acceptance Test (FAT) and EFAT

– Manufacturing Record Books Review

– Material Certificates

– HSE practices review during manufacturing and installation

– Offshore Installation

– Subsea Commissioning

• X-Trees Blocks

– Quality Plan (Project Audits & NCR management)

– Inspection and Test Plans

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing

– HSE practices review during manufacturing and installation

• FLET/ILT

– Quality Plan (Project Audits & NCR Management)

– Inspection and Test Plans

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing applied

– Factory Acceptance Test (FAT) and EFAT

– Manufacturing Record Books Review

– Material Certificates

– HSE practices review during manufacturing and installation

• Jumpers & Spools

– Inspection and Test Plans

– Project Audits & NCR management

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing applied

– Material Certificates

– HSE practices review during manufacturing and installation

• SURF – Rigid Riserlines fabrication

– Project Quality Plan (Project Audits & NCR Management)

– Inspection and Test Plans

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing applied

– Factory Acceptance Test (FAT) and EFAT

– Manufacturing Record Books Review

– Material Certificates

– HSE practices review during manufacturing and installation

• SURF – Pipe-in-Pipe & Stalk Fabrication

– Project Quality Plan (Project Audits & NCR Management)

– Inspection and Test Plans

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing applied

– Factory Acceptance Test (FAT) and EFAT

– Manufacturing Record Books Review

– Material Certificates

– HSE practices review during manufacturing and installation

• SURF – Welded Linepipes

– Inspection and Test Plans

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing applied

– Manufacturing Record Books Review

– Material Certificates

– HSE practices review during manufacturing and installation

• SURF – Riser Pipes & SURF Linepipes

– Inspection and Test Plans

– Non Destructive Testing applied

– Material Certificates

– Mill Test Certificates

– MPQT (Manufacturing Procedure Qualification Test)

– Type 3.2 Certification

– Coatings MPQT

– HSE practices review during manufacturing and installation

• Umbilicals

– Quality Plan (Project Audits & NCR management)

– Inspection and Test Plans

– Welding Maps & Welding Procedures and Specifications

– Welders Qualification

– Non Destructive Testing

– Factory Acceptance Test (FAT)

– Manufacturing Record Books Review

– Material Certificates

– HSE practices review during manufacturing and installation

– Offshore Installation

– Subsea Commissioning

• Project Document Review

– Document Review of EPC Fabrication/Manufacturing Records

– Document Review of EPC Installation/Commissioning Records

– Final Review of Project Handed Over Documentation

– MinPet Audit Observations review & closure